-

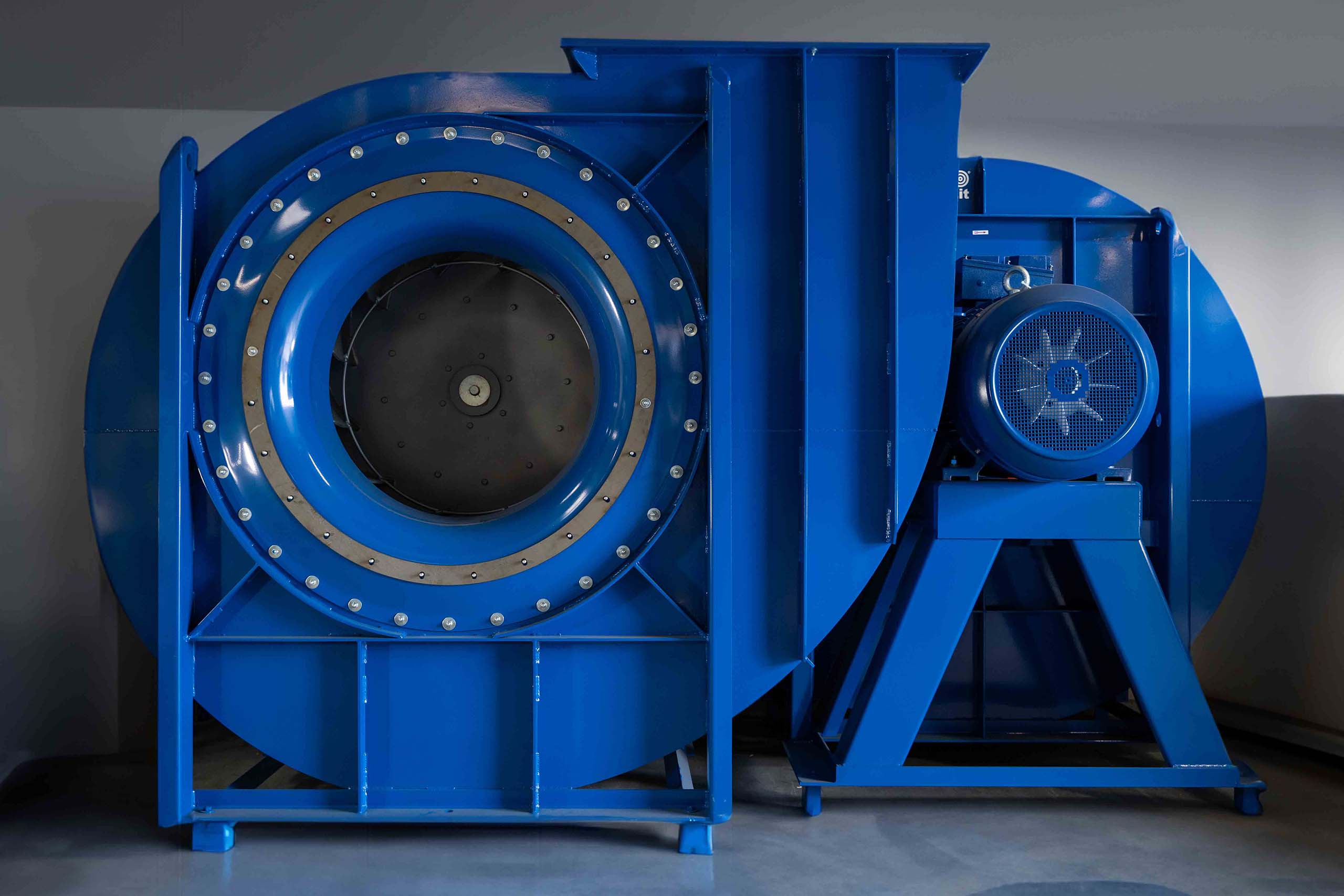

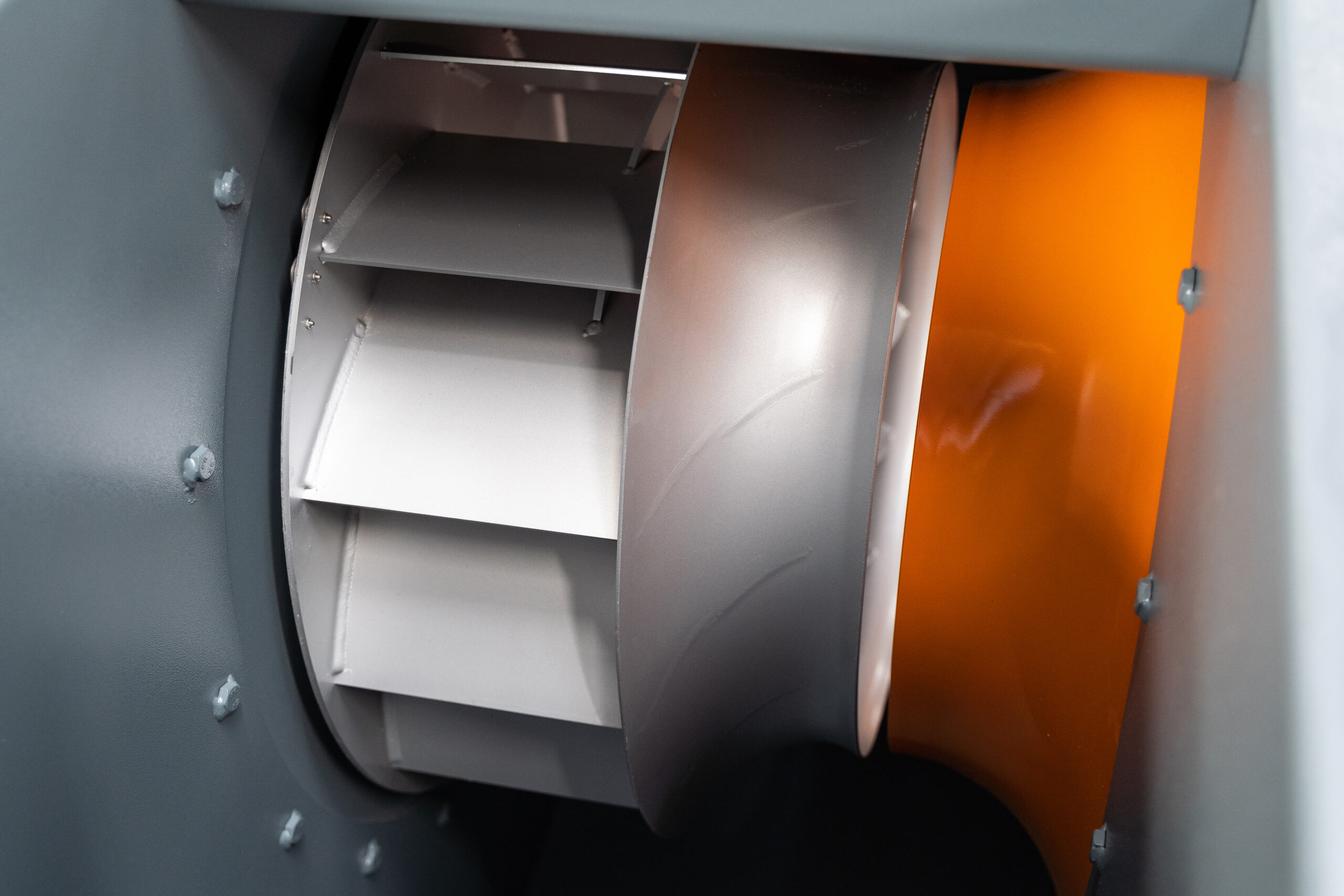

Ventilatori

CentrifughiMovimentare aria pulita o anche molto polverosa, fumi, vapori, gas combusti con portate e pressioni di diversa entità.

-

Ventilatori

Industriali AssialiSi distinguono per caratteristiche dimensionali e costruttive allo scopo di garantire l’utilizzo in differenti condizioni di impiego.

-

Ventilatori

AnticorrosioneVentilatori anticorrosione direttamente accoppiati o a trasmissione con cinghie e pulegge, costruiti con materiali resistenti ad ogni agente chimico.

-

Torrini di Estrazione

Montati direttamente sul tetto dell’edificio, sia ad aspirazione libera sia collegato a canne fumarie e sono dotati di reti anti-intrusione.

Azienda leader a livello internazionale nella progettazione, produzione e vendita di ventilatori industriali

Fin dalla sua costituzione e nel corso degli anni la Moro Srl si è posta come prerogativa essenziale la soddisfazione della sua clientela e ha infatti investito risorse nell’ambito della ricerca e dello sviluppo tecnologico, mettendo a punto una serie di applicazioni sempre più complesse nel contesto della ventilazione industriale che l’hanno resa il punto di riferimento per il settore che è oggi.

I NOSTRI VENTILATORI INDUSTRIALI

Grazie a una strategia di miglioramento continuo, Moro Srl interpreta e anticipa le esigenze di un mercato in continua evoluzione.

Compila il form e riceverai link e password per vedere il video del 40esimo anniversario della nostra azienda.

-

Via Pirandello, 10

20825 Barlassina (MB) – Italia

- P.IVA IT11778090156

- +39 0362 556050

- info@moro.it

- amministrazione@pec.moro.it